4.1.3 Maxwell 3D FEA Results

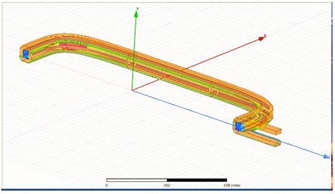

To perform these analyses, a half-model (Figure 10) of the Inventor CAD primary/secondary coil assembly was imported into the Maxwell environment. The CAD models were modified to remove or simplify certain features like bolt holes, and to smooth some chamfer features into fillets. This was necessary to reduce the size of the FEA model and generate a proper meshing of the geometry so that the FEA solvers could function. The coil assembly was also modelled as a half coil to further reduce the size of the FEA model. |

Figure 10. Geometry of the halfprimary/secondary coil assembly-model of the MACE |

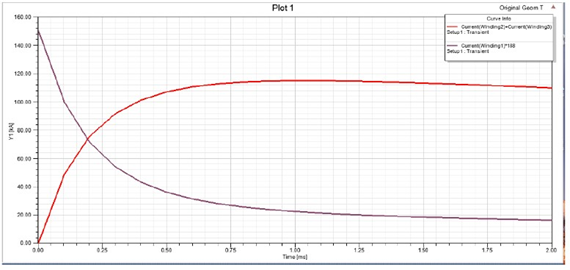

Because the simulation model was half-symmetry, the load coil is split into upper and lower halves; the equivalent load coil inductance is found by a reduction of the equivalent circuit for the parallel connection of both halves and is approximately 2*0.6 μH = 1.2 μH. For comparison in the LTSpice circuit simulations, the superconducting coil inductance was 44 mH and the load coil inductance was 1 μH, indicating close agreement between initial closed form approximate calculations and finite element simulation results. Maxwell3D calculates coupling between the energy storage winding and the load coil is approximately 0.88. A transient finite element simulation was performed for the first 2 msec of the discharge period. The time evolution of the currents in the superconducting energy storage coil and the load coil (Figure 11) indicate that current to the external load will reach a maximum of 118 kA within the first millisecond of discharge.

Figure 11. Time evolution of the currents in the superconducting energy storage coil and the load coil after firing

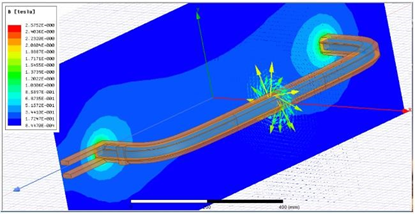

FEA Simulations of MACE Experimental Demonstrator Standby Mode Magnetic Field:

Prior to discharge, the peak magnetic flux density occurs near the corners of the superconducting coil bundle. At the surface of the HTS primary coil, ISIT saw a magnetic field strength a little above the 2 T that was originally calculated (Figure 12). Also, Maxwell3D gives the stored magnetic energy as 8.9 kJ in the half-symmetry model, so the magnetic energy stored by this coil is 17.8 kJ, very close to the design goal of 18 kJ. ISIT noted that the boundaries of the region around the model can affect the energy storage, and ISIT expected that the actual energy storage to be slightly larger.

Figure 12. Steady state magnetic field simulation of MACE coil prior to discharge

Transient Behavior During Discharge:

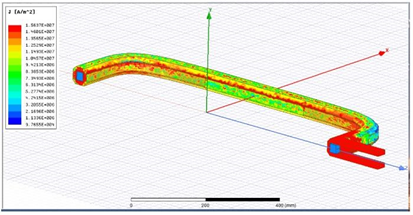

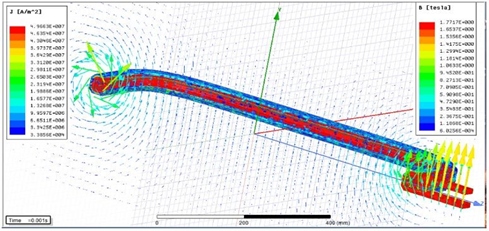

To evaluate primary to secondary coupling in the MACE system and to provide a reasonable starting mesh for the transient discharge case, an eddy current simulation was performed using a 1 kHz 800 A current in the superconducting coil. A stranded superconducting coil is assumed, while the load coil is assumed to be solid copper that will exhibit skin effect current distribution. The load coil is assumed to be connected to a 100 µΩ load resistance which will dominate the current magnitude induced in that winding. A color magnitude plot of the current density in the load coil winding reveals the skin effect distribution (Figure 13). The dynamic range of the plot is somewhat limited, but one can clearly see that the load connection leads on the right side support a higher current density than the main structure of the load coil. This will be addressed in the final design analysis.

Figure 13. Skin effects of current distribution

The magnetic field distribution and current distribution was modelled at 1 msec after discharge (Figure 14). Note that the magnetic field strength has already begun to diminish as energy is transferred to the external load. The “parallel line” construction of the output leads contributes to the B field distribution in the right-hand region of the plot. The current density distribution in the output coil shows higher current density next to the superconducting coil and on the inner surface of the coil due to the eddy current redistribution. The output leads show a high current density also, as was seen in the eddy current simulations; this is primarily due to the high B field density near those leads.

Figure 14. Transient simulation magnetic fields and skin effects at 1 msec into discharge.

These results, together with the other Maxwell3D finite element simulations described above, confirm the initial design parameters and circuit simulation results for the MACE demo coil configuration.