.: Plasma Gasification and Conversion of Materials to Energy

WHY Plasma for Waste to Energy Solutions?

WHY Plasma for Waste to Energy Solutions?

Energy sources which are not harmful to the environment and atmospheric pollution are two of the worlds’ most critical global challenges.

• High temperatures provide different chemistries and chemical kinetics

• Produce higher quality SYNGAS

• Better environmental performance

• Enable efficient processing of wide range of feed stocks (wood, plastic, MSW, medical waste, chemicals, etc)

• Operate efficiently at smaller scale than alternative approaches

• Can be configured for efficient energy production, or production of transport fuels, or chemical feedstocks

• Solid residues are non-leaching vitreous – NOT ASH

This Goal is Not New.

This Goal is Not New.

Economic Waste to Energy Conversion Requires Efficient Heat Sources

For years, plasma scientists have attempted to commercialize direct current plasma generators for convertIng waste to energy.

Plasma waste to energy gasification facilities have been built in Europe and Asia, where land filling is very limited or even prohibited and energy has historically been more costly.

The critical limitation to successful implementation of these plasma gasification facilities, has been the lifetime of the plasma generators and the efficiency and associated economics of the gasification process. The first generation of torches were DC, now they are AC.

High Efficiency Alternating current Current Plasma Generators were developed by the Russians during the Cold War. This technology has been transitioned to the United States and ISIT.

One of mankind’s most critical global challenges is the destruction of our environment through our neglectful disposal of waste materials leading to pollution of our oceans, our atmosphere, and our drinking water. An equally dominant and closely coupled critical global challenge is the means for production of energy from renewable resources without an increase in hazardous materials or other harmful elements to our environment.

The goal of the project was to develop the means to totally destroy waste materials with NO hazardous products by converting the materials to their fundamental atoms and ions. Subsequently, these atoms and ions may then be combined to form an energetic synthetic gas called SYNGAS which can be used to produce electric power. In short, the project converts waste and hazardous materials to useful energy with NO hazardous byproducts.

The technology, developed during the cold war, is a result of recent international collaboration by two of the worlds leading electromagnetic physicists, Dr Fair from Austin, Texas and Prof. Rutberg from St Petersburg, Russia. Dr Fair directed the Institute for Advanced Technology at the University of Texas to provide the scientific underpinnings for the development of hypervelocity electromagnetic railguns. Prof Rutberg directs the Institute for Electrophysics and Electric Power in St Petersburg, Russia , which provides the science and technology for hypervelocity hydrogen launchers. Both research institutes were funded primarily by the US and Russian military departments and became world leaders in Electrodynamics and the use high energy plasmas and complex state of the art electromagnetic high energy and high power devices.

The revolutionary technology they are developing exploits advances in

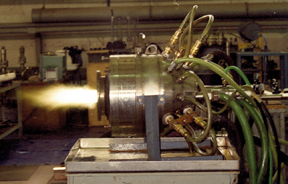

PLASMATRONS, alternating current high energy electric plasma generators, invented and developed by the IEEP in St Petersburg. In recognition for this development, Philip Rutberg was awarded the Global Energy International Prize for 2011. This is the Russian equivalent of the “Nobel Prize for Energy” and is one of the world’s most prestigious prizes for Energy science and technology.

High energy electric plasma generators operate on principles similar to electric arc-welding, where an electrical arc is struck between two electrodes. The high-energy arc creates high temperatures ranging from 3000 degrees to 10,000 degrees Celsius, hotter than the surface of the Sun. The plasma is highly ionized gas. In a plasma waste to energy conversion system, the plasma is enclosed in a chamber into which is fed waste material. The high temperature of the plasma breaks molecules from the waste material into their fundamental atoms or ions. Organic materials such as wood, paper, plastics, oil, paints, food, etc. are broken into carbon, hydrogen and other fundamental atoms or ions. These ions can then be quenched to form carbon monoxide and hydrogen (this combination is known as SYNGAS) which is a combustible gas containing energy similar to the energy content of natural gas. Thermal energy is extracted from the hot SYNGAS and the SYNGAS is fed to a turbine/ electric generator to produce electric power with NO hazardous byproducts.

Solids, such as metals or glass in the waste stream are melted to form a solid glassy slag. This process is NOT incineration, so there is no formation of fly ash or hazardous gaseous byproducts. The vitrified slag is non-leaching and exceeds EPA leach test standards as determined by Standard Toxicity Characteristics Leaching Procedure (TCLP) tests. It can be used for a variety of applications such as rock wool, floor tiles, roof tiles, insulation, landscaping blocks or road aggregate.

Technology Development and Transfer to the United States

During the cold war, the United States and the Soviet Union independently developed plasma generators or plasma torches to study high temperature materials for reentry vehicles on Strategic Ballistic Missiles. The United States developed Direct Current DC plasma systems. Russia developed PLASMATRONS, Alternating Current power supplies and AC plasma generators. Westinghouse has been the major producer of DC torches and has sold them throughout the world, although several other companies in the United States and Canada now manufacture DC torches.

In Russia, the high energy, high power PLASMATRON AC plasma torches were developed by the Institute for Electrophysics and Electric Power (IEEP) , a research institute of the Russian Academy of Sciences in St Petersburg, Russia. No commercial or industrial market was developed and the technology has not been well publicized outside of the former Soviet Union.

Following the demise of the Soviet Union, the United States funded former Soviet weapons laboratories and scientific experts to pursue peaceful/commercial uses of their technologies. Professor Philip Rutberg, Director of the IEEP, was funded by the United States and by the Russian Academy of Sciences to explore the destruction of medical waste using PLASMATRON AC high energy plasma generators. Unfortunately, the Russian equipment was not commercially available and the AC plasma results not publicized in the West, so consequently, all of the 30 or more plasma waste to energy conversion facilities around the world are based on DC plasma systems.

Successful Transfer of the PLASMATRON AC Plasma Technology to the United States

Independent investigations by Dr. Harry Fair and his colleagues at the Institute for Strategic and Innovative Technologies, indicated that the PLASMATRON AC plasma generator systems could have major important advantages over the DC plasma generator systems developed by the United States, particularly in terms of scaling, efficiency and cost of operation. ISIT provided funding to import the Russian PLASMATRON AC plasma generator technology to the United States and to experimentally validate the performance of the PLASMATRONS. In late 2009, ISIT was able to acquire first and second generation high energy, high power PLASMATRONS and their power supplies from the IEEP in St Petersburg, Russia. ISIT established a research and testing laboratory in Austin, Texas and with the collaboration of Professor Rutberg and his colleagues at the IEEP, has validated in the United States, their performance. ISIT also provided funding to the IEEP to design a compact PLASMATRON AC plasma generator system to convert 50 to100kg/hr of wood to SYNGAS. The rationale is that wood is high in organic content and a good prototype material for evaluating the efficiency and throughput of the AC system for a broader class of waste or other organic products. Additionally, he provided funding to the IEEP to convert their pilot facility in St Petersburg to experimentally validate their computations on the performance of converting wood to SYNGAS. The experimental results validated the computations and determined the performance parameters to obtain high quality (rich in hydrogen) SYNGAS. ISIT also purchased a detailed design from the IEEP for a compact, transportable high energy high power PLASMATRON AC plasma system for converting wood or other organic waste to energy.

The lifetimes of the plasma generator electrodes are critical in establishing the commercial viability and economic feasibility of these systems for converting waste to energy. They have been determined by calculations and experiments at the IEEP for the first generation AC systems. The new 2nd generation electrode lifetimes are predicted to be much higher, and are in the process of experimental validation. Further, both IEEP and the ISIT are continuing research on advanced electrode materials exploiting nano-structured power metallurgy to obtain even longer lifetimes. The 2nd generation AC plasma torches produce 30-50 kW. For a full scale waste to energy conversion system, higher energy torches will be required. The IEEP is now testing a 300-500 kW AC plasma torch which is demonstrating excellent results with very good lifetimes of the electrodes and thus operating lifetime. Current projections give an estimated electrode lifetime of in excess of 1000 hours. The importance of this for commercialization is that this can enable 24/7 operation of a waste to energy system for many weeks of continuous operation. Electrode replacement is fast and simple and would be scheduled as part of routine system maintenance.

Competitive Approaches and Facilities

Landfills, dumping at sea, and incineration have been the primary means of disposing of our waste. All of these are no longer acceptable. Plasma technology offers a new environmentally sound approach with NO harmful byproducts and which also produces electric power from renewable sources.

Plasma Technology is NOT incineration.

The use of plasma generators to create extreme temperatures – is not new. They were developed by both the Russians and the United States for the purpose of testing heat shields for spacecraft and reentry vehicles in the 1960s. As noted in the Dovetail Report (reference 1)

“Although plasma arc technology is not new, adaptation of this approach to large-scale solid waste disposal is, including gasification of waste and recovery of energy from the gas generated. As noted by Dodge (2009) “Plasma gasification of mixed solid waste (MSW) is a fairly new application that combines well-established sub-systems into one new system. The sub-systems are waste processing and sorting, plasma treatment, gas cleaning, and energy production. The integration of these systems is rapidly maturing, but has still not been built in large industrial systems.”

There are at least a dozen companies planning municipal plasma waste to energy projects, and in fact, there are several small plants operating in Japan, converting significant amounts (80 to 100 tons/day) of municipal waste to energy.

Incineration is an entirely different process. Incineration or combustion occurs in the presence of an excess of oxygen at temperatures in the 1,000 to 2,000 deg F range and incinerators manage polluting emissions by scrubbing out the ash and other byproducts and their main function is to reduce the volume of waste to ash ( 30 to 50%). Ash is then generally land filled, with the content of ash often requiring treatment as hazardous waste.

In contrast, electric plasma arc gasification is the complete conversion of waste or organic materials to synthesis gas and inert slag with recovery of energy and valuable metals and occurs at temperatures above 2000-5000 F with no polluting byproducts. (The plasma torches can operate to 10,000 F but the reactor operates at lower temperature to protect insulating components).

Competitive Advantages of Alternating Current Plasma Generators Versus Direct Current (DC) Plasma Generators

There are significant and important differences between Direct Current and PLASMATRON Alternating Current Plasma generators and their plasmas. Alternating Current generators have a high coefficient of energy transformation of the plasma arc into gas energy (higher than70-90% versus 50% for DC)). Since the purpose of the plasma is to heat a volume of the reactor to high temperature, the plasma should cover a broad volume and be diffuse in contrast to a highly focused pencil beam. With the AC plasma generator, it is possible to control the mode of the plasma arc to be diffuse, leading to the high efficiency of energy transformation. Importantly, the AC power supplies are simple conventional AC transformers which are cheaper to purchase and operate than specialized DC power supplies. Further, the alternating current electrodes are easily replaced enabling a minimum of downtime for system maintenance. DC plasma generators require expensive distilled de-ionized water for cooling versus ordinary tap water for the PLASMATRONS.

Most importantly, the overall AC system efficiency is significantly higher than for DC systems leading to significantly lower operating costs and MUCH greater electric generating capability.

Plan for Commercialization of AC Electric Plasma Torch Technology

The Institute for Strategic and Innovative Technologies has created spin-off companies to commercialize the technology and will continue collaboration between its in-house research laboratories and the IEEP in Russia to further advance the technology. The ISIT will also construct and operate pilot facilities for converting waste and other organic materials to electric power to further optimize the conversion process. The ISIT plans to operate the pilot facilities through the test and evaluation phase.

1) Oaks Plasma, LLC has been formed to hold the intellectual property and to license it to companies interested in commercializing the technologies. The initial patents concern PLASMATRON AC plasma torches, but additional patents, technologies and applications will be included in the Oaks Plasma portfolio.

2) Fair Oaks Plasma, Inc. was formed to obtain PLASMATRON AC plasma generators through contracts with the Russian Institute and to establish a research and test facility and the necessary infrastructure to operate the generators to validate their performance. This has been successfully accomplished. Fair Oaks also determined that the level of technology is excellent but was developed as state of the art laboratory equipment by the Russian research laboratory IEEP for operation and experimentation in Russia. The equipment needs to be reconfigured to meet Western and European industrial safety standards.

Fair Oaks Plasma Inc. has been disestablished and the plasma equipment donated to the non-profit Institute for Strategic and Innovative Technologies to establish a plasma research and technology development laboratory at the Institute to continue the development and transfer of AC plasma technology.

3) Plasma Technology Applications, Inc. (PTA) has been created to engineer, redesign and manufacture PLASMATRON AC plasma generators, their power supplies and reactor systems in the United States. The equipment obtained by Fair Oaks Plasma from the IEEP is NOT "Westernized" in that the electrical components particularly need to be redesigned to meet United States and European safety standards. An engineering design, analysis and documentation team will ensure compatibility with Western industrial safety standards and provide the necessary instruction manuals and related documentation. Equally important is the need to establish a manufacturing capability for all of the components in the United States- for the initial production and for the manufacture of spare parts. This activity will be accomplished in close collaboration with the engineers from the Institute for Electrophysics and Electric Power through agreements between the ISIT and the IEEP. The intent is to provide the capability of manufacturing all of the critical components including reactors, controls, and associated process equipment and the Power and electrical equipment and controls to provide a "turnkey" system.

PTA will market its products, train operators/users, provide technical support during system start-up, provide engineering/technical support to design engineers and prospective clients, produce product specifications and provide engineering services and support for operating plants.

Parties interested in helping commercialize the AC plasma technology should contact Dr. Harry D. Fair, Director, Institute for Strategic and Innovative Technologies, fair [at] isitaustin.org.