5.5 STRUCTURAL ANALYSIS

![]()

5.5.1 Finite Element Analysis of Structure

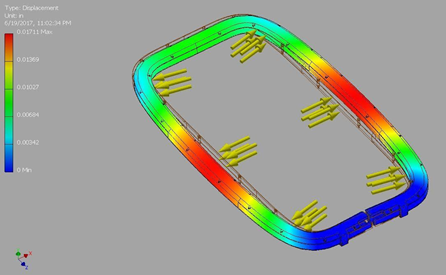

Stress analysis of the primary/secondary coil assembly was performed using the structural FEA tool within Autodesk Inventor 2017 (Figure 33). The main concern here was that magnetic pressures generated during operation of the device would be strong enough to force significant deflections in the coil form structure, thereby generating strain on the HTS superconducting tape within the primary coil. The FEA simulation shows that a maximum deflection of 0.017 in occurs at the midpoint of the long edges of the coil. This generates a strain of only 0.00005%, or much less than the 0.1% strain tolerance of the HTS tape.

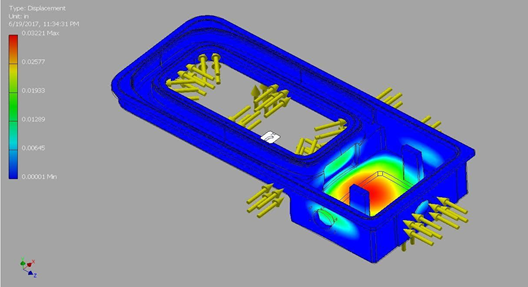

An analysis of deflection in the polymer vacuum vessel (Figure 34) showed negligible deflection throughout most of the structure. However, the large enclosed volume containing the cryocooler, leads, and other components showed enough deflection to justify adding two support pillars within the volume to maintain the integrity of the structure and ensure a good vacuum seal.

Figure 33. Deflection under load during operation of the primary/secondary coil assembly.

Figure 34. Deflection of vacuum vessel under atmospheric pressure

6 SIGNIFICANT HARDWARE DEVELOPMENT

![]()

No physical hardware development occurred during this period since Phase I was only a feasibility study of the MACE concept. ISIT did create, however, a full CAD model of the MACE Demonstration Unit which will be built in a future Phase II of the MACE program.

![]() .

.

7 SPECIAL COMMENTS

![]()

The conclusions from the Phase I Feasibility Study of the MACE concept indicate that the annular SPPT design represents a significant improvement in the state of the art for SPPTs.

8 IMPLICATIONS FOR FURTHER RESEARCH

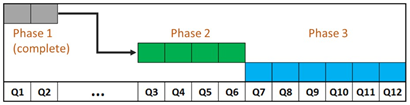

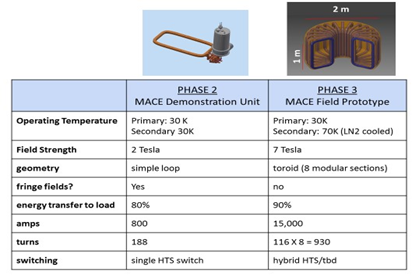

In our initial proposal for the MACE program, ISIT proposed that after completing the Phase I Feasibility Study ISIT would then proceed to building prototypes in Phases II and III (see Figures 35 and 36). Phase II (“Option 1” in the proposal) is a 12-month program to build the MACE Demonstration Unit described in this report. Phase III (“Option 2” in the proposal) is an 18-month program to build the MACE Field Prototype which would be a realistic test of the MACE concept under field conditions. The MACE Field Prototype would deliver 10 MJ of energy with 90% efficiency in under 10 msec to a realistic external load (most likely a railgun). Additionally, the MACE Field Prototype will be in a toroidal configuration that would minimize external magnetic fringe fields so that the unit could be operated in close proximity to personnel and sensitive equipment.

8.2 MACE PROTOTYPE DEVELOPMENT ROADMAP

In our initial proposal for the MACE program, ISIT proposed that after completing the Phase I Feasibility Study ISIT would then proceed to building prototypes in Phases II and III (see Figures 35 and 36). Phase II (“Option 1” in the proposal) is a 12-month program to build the MACE

Demonstration Unit described in this report. Phase III (“Option 2” in the proposal) is an 18-month program to build the MACE Field Prototype which would be a realistic test of the MACE concept under field conditions. The MACE Field Prototype would deliver 10 MJ of energy with 90% efficiency in under 10 msec to a realistic external load (most likely a railgun). Additionally, the MACE Field Prototype will be in a toroidal configuration that would minimize external magnetic fringe fields so that the unit could be operated in close proximity to personnel and sensitive equipment.

Figure 35. Duration of Phase 2 and Phase 3

Figure 36. MACE Design Targets for Phase 2 and Phase 3

Originally, Phase II was envisioned to begin immediately following the completion of Phase I. However, the project is currently talking with potential funding agencies that might be willing to contribute funds to Phases II and III.

PHASE 2: KEY SUPPLIERS, SUBCONTRACTORS, AND FACILITIES

During Phase I, ISIT identified key suppliers, subcontractors, and facilities that would be required to complete Phase II.

8.2.1 HTS Supplier SuperPower Inc.

450 Duane Avenue

Schenectady, NY 12304 USA

8.2.2 Coil Winding HTS-110

1B Quadrant Drive

Lower Hutt 5010

New Zealand

Or

SuperPower Inc.

450 Duane Avenue

Schenectady, NY 12304 USA

8.2.3 Coil Form and Dewar Manufacture Atlas Technologies

305 Glen Cove Road

Port Townsend, WA 98368 USA

8.2.4 Cryocooler Cryomech, Inc.

113 Falso Drive

Syracuse, NY 13211 USA

8.2.5 Main Unit Vacuum Vessel Marine Science Development Center

Scripps Institution of Oceanography

9500 Gilman Drive

La Jolla, CA 92093 USA